Products

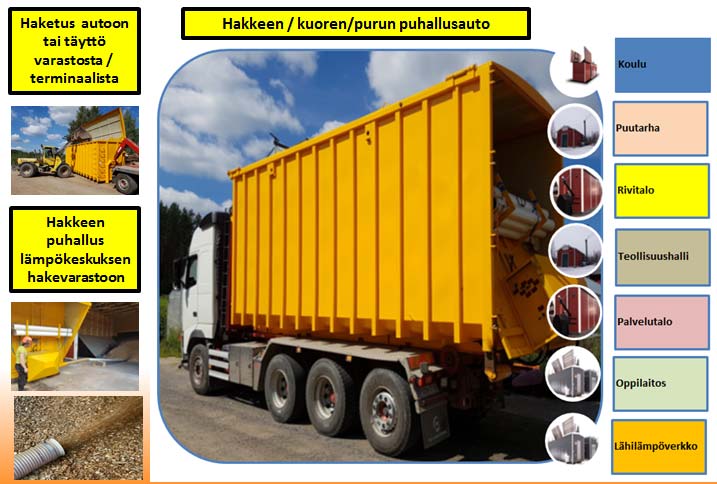

What is pneumatic woodchip blowing technology?

Characteristics of pneumatic blowing technology:

- Woodchips are blown directly from vehicle to the woodchip storage silo of the mobile heating plant container. The blower is installed on the rear end of the vehicle.

- The woodchip blower can be installed on different types of vehicles and containers.

- The blower is driven by the hydraulic system of the vehicle.

- There are also electric motor or diesel engine driven blowers.

- Different kind of woodchips, bark, saw dust, straw etc. can be handled with the blower.

- The optimal speed of rotation of the turbine is 4500 rpm.

- Blowing distance may be 20 – 80 meters or the woodchip delivery height about 20 meters depending on the blower type and material to be handled. Woodchips can be blown also into places with limited approach with the vehicle.

- The capacity of the blower is 0,3 – 1,2 m3/min with typical materials. Pneumatic woodchip blowing has been designed especially for small scale heating units where the unloading time is not a critical issue. The main idea is to make it possible to utilize woodchips by flexible fuel delivery system and mobile heating units.

- The blower can operate also in suction mode, e.g. when cleaning woodchip or pellet silos.

- In addition to bioenergy applications pneumatic blowing technology can be utilized in several other business lines.

FACT BOX

Main components of the solution

The new woodchip logistics and heating plant concept is based on two main components:

- Blowing vehicle equipped with a woodchip blower wall

- Mobile woodchip heating container 50 – 700 kWth

Materials to be handled

Different materials can be handled pneumatically with the woodchip blower: woodchips, flowing crushed bark, saw dust, straw etc. When blowing pellets a different type of blower arrangement will be applied. The blower can operate also in suction mode.

Capacity

There are four different types of blowers in terms of capacity: models 400, 500, 600 and 700 (the diameter of the turbine). The capacity varies between 0,3 and 1,2 m3/min depending on material to be handled and blower type.

Driving force

The driving force of the woodchip blower is the hydraulic system of the vehicle, electric motor or diesel engine.

A new logistic solution to replace oil with bioenergy in small heating plants

The solution consists of two elements: a woodchip blower and a mobile heating unit provided with integrated woodchip silo. The purpose of the solution is to make the whole small scale woodchip heating system chain more cost effective. Investment costs of the solution are smaller than those of conventional heating systems. Fuel receiving equipments and storages are simple in mobile heating containers. No tipping sites or underground fuel storages are needed. The same vehicle can serve several heating plants. The solution is a cost effective way to promote replacing oil with bioenergy and is an action towards carbon free economy in small scale heating.

Lämpösi Oy is co-operating with the Lappeenranta – Lahti technical university to develop this new logistic solution for small woodchip heating plants. The university has launched a project called “Puhallus” to study the compatibility and market potential of the solution.

Mobile woodchip heating container

- A mobile heating container manufactured at engineering works can be easily installed and commissioned

- Construction work at site is minimal. Sinking costs can be avoided when using a mobile heating unit in case of changes in business circumstances

- In larger heating units a separate larger woodchip storage container can be used to optimize fuel delivery schedules

- Space requirements are modest. The mobile unit can be situated in tight locations

- Flexible financing tools can be utilized for a mobile unit (leasing)

- A mobile heating unit can be easily replaced by a larger or smaller unit, or transferred to another site if needed

- It is easy to start heating with woodchips, or start heat sales business with small risks. Oil can be replaced by mobile heat containers temporarily in areas close to a DH network until the areas will be connected to the main DH grid later.

- There are several manufacturers who provide mobile woodchip containers. In choosing case by case an appropriate product consultant help is available.

Examples of woodchip blower applications (some of the applications would be tailored and manufactured on special order)

Woodchip blower wall installed on an interchangeable container

- Tipping interchangeable container (well flowing material)

- A container provided with a walking floor unloading

- A container provided with a chain conveyor floor

- A composite material based tipping interchangeable container

Pellet blower

- Tipping interchangeable container (well flowing material)

- A container provided with a walking floor unloading

- A container provided with a chain conveyor floor

- A composite material based tipping interchangeable container

Woodchip blower

- Electric motor driven woodchip blower

Woodchip blower

- Thermal diesel engine driven woodchip blower

- On special order

Woodchip blower

- Mobile woodchip blower trailer driven by thermal diesel engine

- On special order

Pellet blower

- Independent pellet blower unit

- On special order

Woodchip blower

- The blower can be operated also in suction mode

A woodchip container provided with a woodchip blower

- On special order

Dual blower for both woodchips and pellets

- Both woodchips and pellets can be blown with the same blower by changing the blower settings.

- Changing the blower settings can be easily done.

Woodchip blower can be applied on several business areas

Heat entrepreneurs

- Woodchip supply for own heating plants as well as outside deliveries

Woodchip suppliers

- Woodchip supply

Transport companies

- Additional material delivery services

Pellet suppliers

- Pellet deliveries

- No expensive pressurised tank lorry is needed

Green area infra construction

- Spreading cover materials on bare soil areas and decorative purposes or landscaping

Agriculture

- Straw, woodchip, grain, feed, fertilizer etc.

Industry

- Granules, pellets, saw dust, insulation materials etc.

Skiing centers

- Covering snow storages with saw dust

Other applications

- -